Physical Therapy Leggings

This was my Mechanical Engineering Senior Capstone Project for undergrad at Wentworth Institute of Technology. Completed in 2019 as a team of 4 students.

Skills

Design Engineering, Prototyping, Material Testing

My Role

I led the research of anatomy and the design/build of the silicone knee.

Background

Injuries to the knees often develop with age, but can also affect younger people who are involved in sports. These injuries are often due to repetitive motions, instability, weight, or impact. The knee is the largest joint in the body, and one of the most easily injured. Not only is the knee easily injured, but it is also vulnerable to a variety of injuries because it is a complex joint with many components. Since these injuries are so common, and often unpreventable, the team found it necessary to create a solution that would not only aid the healing process of past injuries, but also prevent future ones.

Many knee injuries can be successfully treated with simple measures, such as bracing and rehabilitation exercises. While there are preexisting solutions to treating injuries, it has been found that they are not often used to prevent injuries, and they also tend to be bulky and awkward. Over the course of this project, it was the goal to create a way to support the knee in everyday use, and especially in physical therapy sessions.

Objectives

The primary purpose of this project was to create an apparatus that accurately demonstrates the knee to use for testing of materials. There are set functional specifications for this knee apparatus to prove that it accurately models a human knee. These specifications are as follows:

• the knee joint can move up to 160 degrees in flexion and -5 degrees in hyperextension

• the knee can internally and externally rotate between 25-30 degree while in flexion

• a radius of 1.5”-2.5” for males

• a radius 1.5”-2.7” for females

• the knee can internally and externally rotate between 25-30 degree while in flexion

• a radius of 1.5”-2.5” for males

• a radius 1.5”-2.7” for females

After creating the knee apparatus, the goal was to develop a pair of leggings that prevented unwanted lateral movement in the knee. This solution had to allow for vertical movement (bending of the knee) and limit lateral movement to stabilize the knee. This component of the project involved layering materials in such a way that the brace is supportive, yet bendable for physical therapy and injury prevention. The compression brace was incorporated in leggings for everyday use. The end product was able to provide support for a variety of knee sizes and body types.

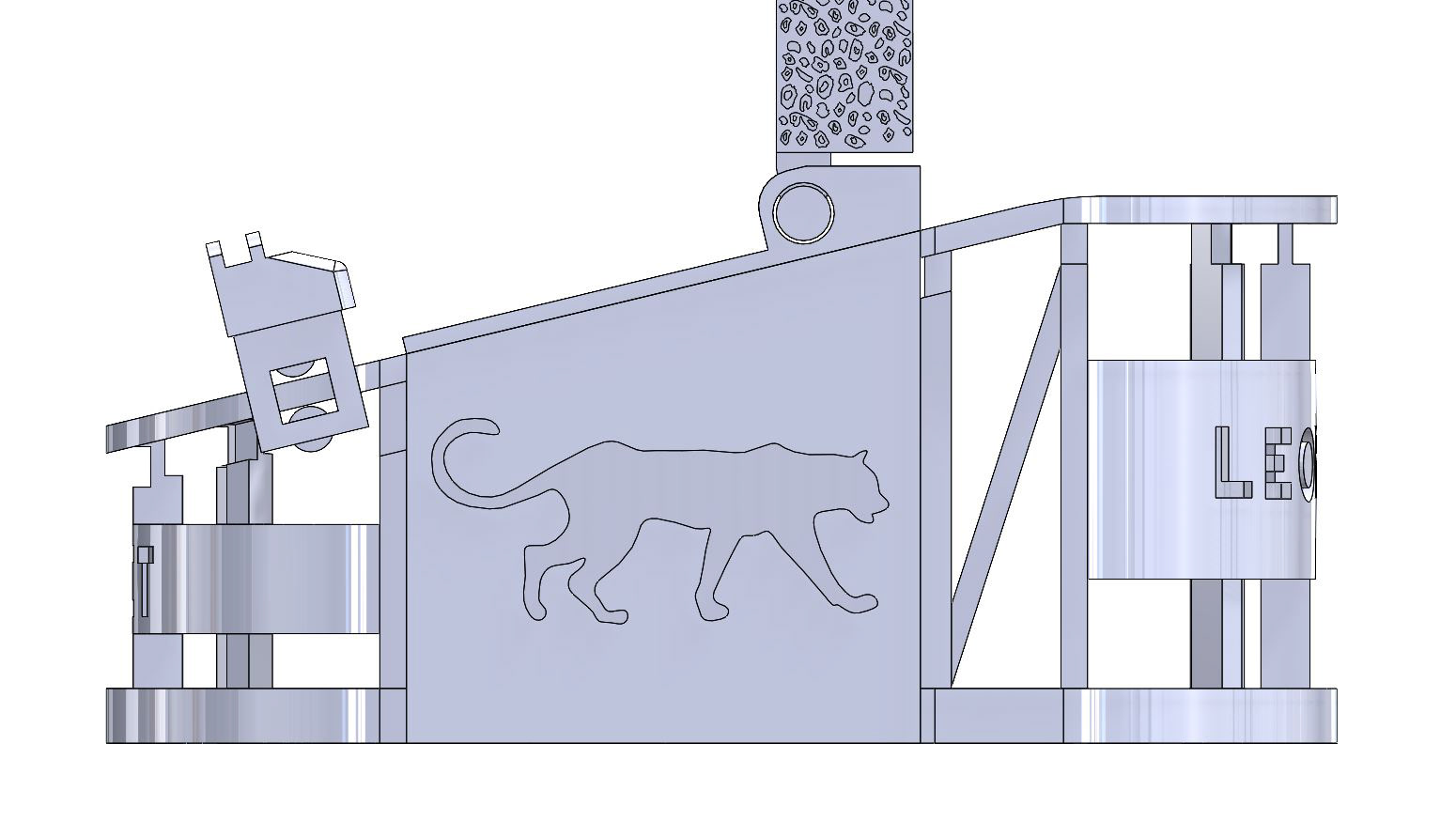

Test Apparatus

To create our testing apparatus, we casted one of our teammate's legs to create a mold that would then be filled with Dragon Skin (a silicone material). The mold was created using plaster, which is typically used for casting broken bones, and the inside was painted with resin once it was dry.

A heim joint and clevis were used to help model the movement of the knee by allowing flexion and extension. Combined with rods that went through the mold of the leg to model the bones, this allowed the apparatus to be adjusted to determine the optimal motion for accurate knee testing.

Material Testing

We used an Instron machine to determine the stress and strain different materials can withstand, as well as the deflection they undertake. The Instron test included Kevlar, nylon, and various compositions of spandex. The test pulled the material to failure to then determine the delta deflection verses the force applied to the material. The Instron test data provided the project with the modulus of elasticity and other information for the materials, which assisted in determining the materials that should be used to create support around the knee.

Next, the knee apparatus was tested with a section of leggings that had Kevlar, nylon, or no additional support sewn onto the leggings. Two different sets of data were obtained from this: extension testing and deflection testing. In the extension testing, the amount of force required to extend the knee from the original 140° to 160° was measured. This was measured in order to prevent the leggings from restricting movement in the extension/flexion direction. The second test was the amount of deflection when the leg was pulled with 25lbf laterally.

From these tests, it was determined that the best combination of materials to pursue for the prototype leggings was the gray spandex with the addition of the nylon strapping.

User Testing

Once we determined the materials for our PT leggings, a teammate of mine sewed a pair of leggings with our brace design on them. The user sampled the leggings while performing various activities and gave us feedback on comfort and fit.

From our user testing, we found that our leggings provided more overall knee stability than normal exercise pants. Also, our leggings reminded the wearer to use the correct form when exercising because the straps on the knee kept their knee in place.